Steel Decarbonising Construction

Jo Clarke explains the role of steel in construction as the industry aims to decarbonise.

Steel in construction

We use over 50% of world steel in construction. Steel’s inherent properties, strength, versatility, durability and 100% recyclability, provide improved environmental performance across the whole life cycle of buildings. Due to steel’s versatility, we can use it within several building elements. This includes structural sections, roof and wall cladding, building services and fittings.

There are many benefits of steel. Steel is relatively lightweight compared to other structural materials such as concrete. This benefits transportation, resource efficiency and assembly, as well as impacting on the type and extent of foundations. In fact, we can use steel as an alternative material to concrete for foundations.

We can manufacture lightweight offsite solutions for buildings using steel. With this approach we reduce waste materials and minimise onsite labour and the costs and carbon generated by onsite activities. We also reduce overall construction time.

Steel in Active Buildings

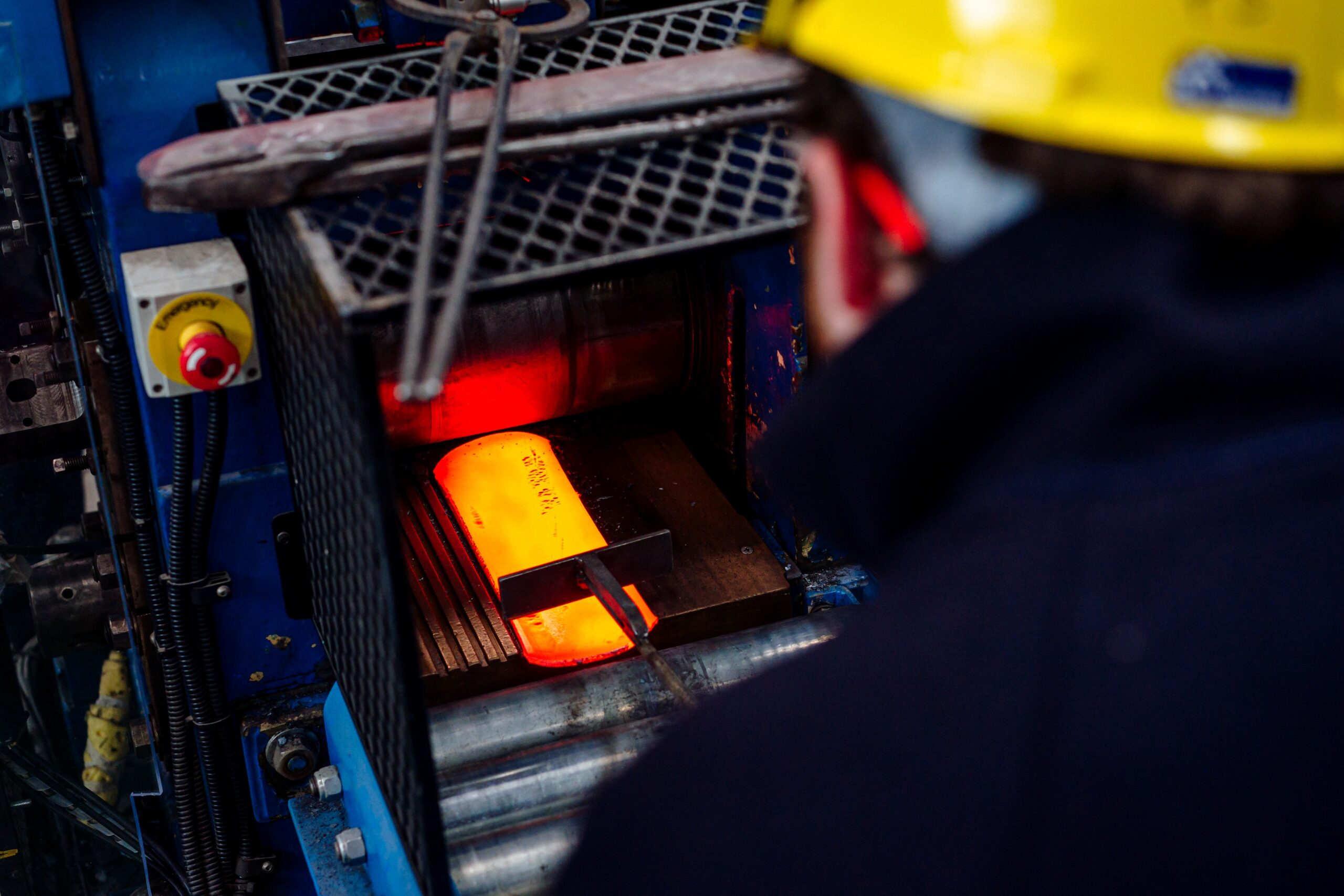

As we address carbon targets the high embodied carbon of steel makes it an increasingly difficult choice of material . The good news is there are ways we can reduce the carbon footprint of steel. The steel industry is already developing low carbon steel solutions.

Our Active Building demonstrators showcase innovative low carbon steel products, enabling feedback on their performance in a real-world environment. With our demonstrators we highlight the benefits of UK steel and how innovative steel products can help create sustainable buildings.

Steel framed building

We constructed our Active Classroom using a novel steel-framed panelised system. We utilised Welsh manufactured light gauge steel developed by a small company seeking to showcase their system on a real building.

The simplicity of their system allowed us to erect the whole building with very little time, effort or equipment. In theory, the design allows the building to be deconstructed. The panels could be reused on another building at the end of the building’s life.

The panelised system is lightweight and requires no additional structural supports. Therefore we designed the building to sit on a series of steel screw pile foundations instead of using concrete. At the end of the building’s life the screw piles can be removed and reused for another building. The lighter panels and foundations mean they are easier to move, reducing time, transportation and fuel use.

Steel walls and roof

The outer skin of the Active Classroom showcases Tata’s novel, pre-commercial Colorcoat Prisma® cladding. Their three-layer manufacturing technology creates a robust, chrome free pre-finished steel product in a range of colours.

We selected colours to match the surrounding landscape and buildings on Swansea University’s Bay Campus. The south elevation is black to maximise the absorption of solar energy as a renewable heat source. Internally we used Tata Coretinium® as a wall lining providing magnetic ‘idea walls’ within the teaching space.

We used a precommercial building integrated photovoltaic roof manufactured by Welsh company BIPVCo. This comprises a series of thin-film PV panels bonded onto steel roof sheeting to form a lightweight, electricity generating roof covering, with very low impact aesthetics.

Steel speeds construction

Using all the steel-based systems sped up construction time considerably. Importantly, we significantly reduced the associated carbon emissions of a construction site. That’s from the steel foundations, to the panelised superstructure, and the energy generating roof, and onsite operations.

The ease of erection of the steel intensive building and lack of wet trades meant construction could continue in all weathers. This helped us meet our tight programme.

Recycle and reuse of steel

As we strive to meet carbon targets, steel producers must seek ways to significantly reduce the embodied carbon of steel. One way to do this is to maximise its reuse.

Tata Steel are introducing a “Tag and Track” system marking their product range with a QR code to maintain a record of where every element is used, to ensure steel is used fully for its entire lifetime. Their plans include creating materials passports and collecting in-use performance data from all their products, providing full product provenance.

This would allow more reuse of steel. It would reduce the amount of new steel needed. And it would reduce the carbon emissions, energy and resources of steel production. Designers can assist the reuse of steel products through designing bolted connections rather than riveting or welding, and using standardised sections and components.

Recycled steel has approximately one fifth of the carbon footprint of virgin steel and uses roughly one third of energy used in producing new steel. In the UK and globally the demand for steel currently exceeds the supply from demolished or scrapped steel. As we use more steel we increase the proportion of recycled steel to virgin steel.

Steel in a low carbon built environment

To meet our carbon targets, we need to think carefully about the way we use resources. For the construction industry aiming to decarbonise, the beauty of steel lies in its versatility, its role in offsite construction, its reusability and its recyclability.

Building designers, contractors and the whole construction supply chain have a massive part to play in ensuring resource efficiency. The materials we choose and how we deploy them has a substantial impact on the whole-life carbon of buildings.

There is a real opportunity for steel to lead the way in developing low carbon solutions for buildings. Our Active Classroom is a successful demonstrator of this.

Contributor Jo Clarke

January 2022

Jo is Design Manager for SPECIFIC IKC, and is a multi-award winner for her Active Building demonstrators