Regional steel innovation

SaMI was founded at Swansea University a longstanding member of the steel community.

The institution plays a key role in steel innovation through close collaboration with industry.

Swansea University was founded to support industry in the south Wales region and experts at the institution have been working with steel, and the wider manufacturing industry, ever since.

The region is famous for its expertise in steel and metals and an ideal setting for SaMI as we help industry innovate and transition for a decarbonised future. It is a real opportunity for the steel industry to decarbonise. Making steel was traditionally a carbon-intensive business but the industry is improving fast.

Steel innovation at Swansea

Steel endures. As the world’s most recycled material steel can be recycled infinitely with no loss of quality. Many steel products don’t need recycling very often. The average life span of a steel product is 40 years: shorter than this for a drinks can, but a lot longer for bridges.

Swansea University is heavily involved in steel innovation. Teams are inventing new coatings to extend steel’s lifespan even further and developing new steels as strong as current options but lighter. Around 3500 grades of steel are in use today, and 75% of them didn’t exist 20 years ago.

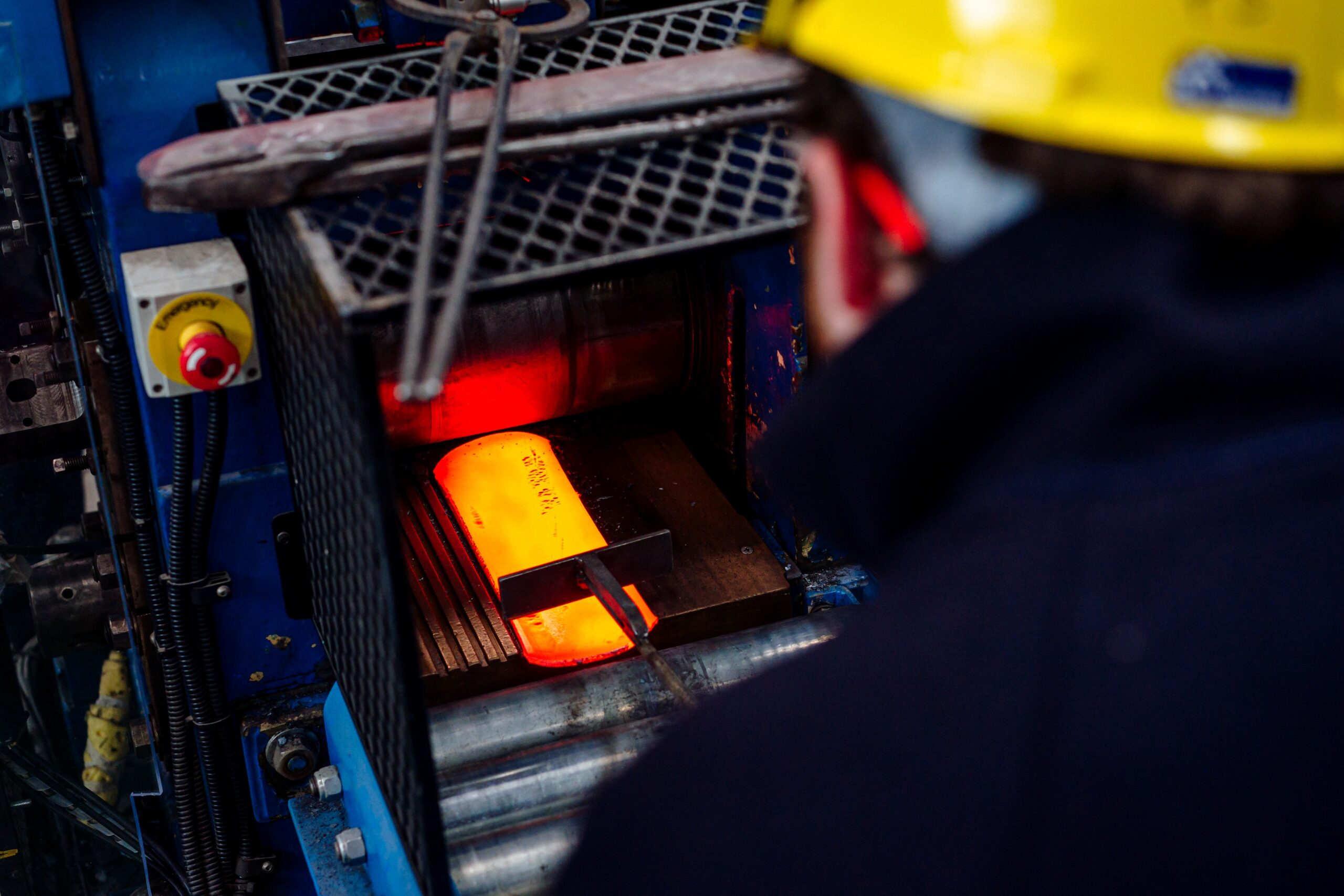

To make steel fit for a net zero society we need steel that is responsive to customers. Steel driven by data. Steel that is zero carbon. Today’s steelmaking is about laboratories and laser testing as much as blast furnaces and chimneys, hi-tech and highly skilled.

Steel innovation for industry

To address the wider environmental impact of the steel industry, we need to innovate products as well as the manufacturing process. Wind turbines are 80% steel. Rails for train travel are 100% steel. Electric vehicles need specialist electrical steels in their motors and generators.

The Specific project based at Swansea University designed and constructed buildings that generate, store and release their own energy. Steel innovation plays a key role in these innovative ‘Active Buildings’. They are built with a new steel developed by Tata Steel with tiny perforations in it. The sun warms the steel and a boundary layer of air, which is drawn into the building through the perforations, providing renewable heat.

Addressing energy in buildings is essential for decarbonisation. Combined with other technologies, like solar panels and batteries, the result is buildings that can be energy positive. The energy surplus can charge electric vehicles and supply neighbouring buildings.

Steel decarbonisation

Steel is often misunderstood as an old-fashioned industry. In fact, it is an indispensable part of the future. Steel is the most commonly used metal in the world and the most recycled material. Almost everything we use is either made of steel, or made using steel, and often both. If we want a cleaner, greener future, then we need steel.

At SaMI our initial focus on steel innovation has seen us expand to help deliver practical solutions to other sectors. We are not only helping the steel industry innovate – we are helping other industries in the challenge to transition towards decarbonisation. SaMI is one of a number of projects coming together with industry to help decarbonise the region. This regional collaboration called SWITCH will help accelerate Wales’ transition to Net Zero.

Our 100-year relationship with the steel industry continues as we work together to innovate steel fit for a green economy and a net zero society. And collaborate more broadly to help accelerate the region’s industrial decarbonisation

Contributor Kevin Sullivan, Senior Press Officer for Swansea University

March 2021