Developing bespoke alloys

We are creating and developing bespoke alloys for industry.

Building on our expertise gained from supporting the steel industry we are now melting other metals and non-ferrous materials such as glass.

Refining elements for industry

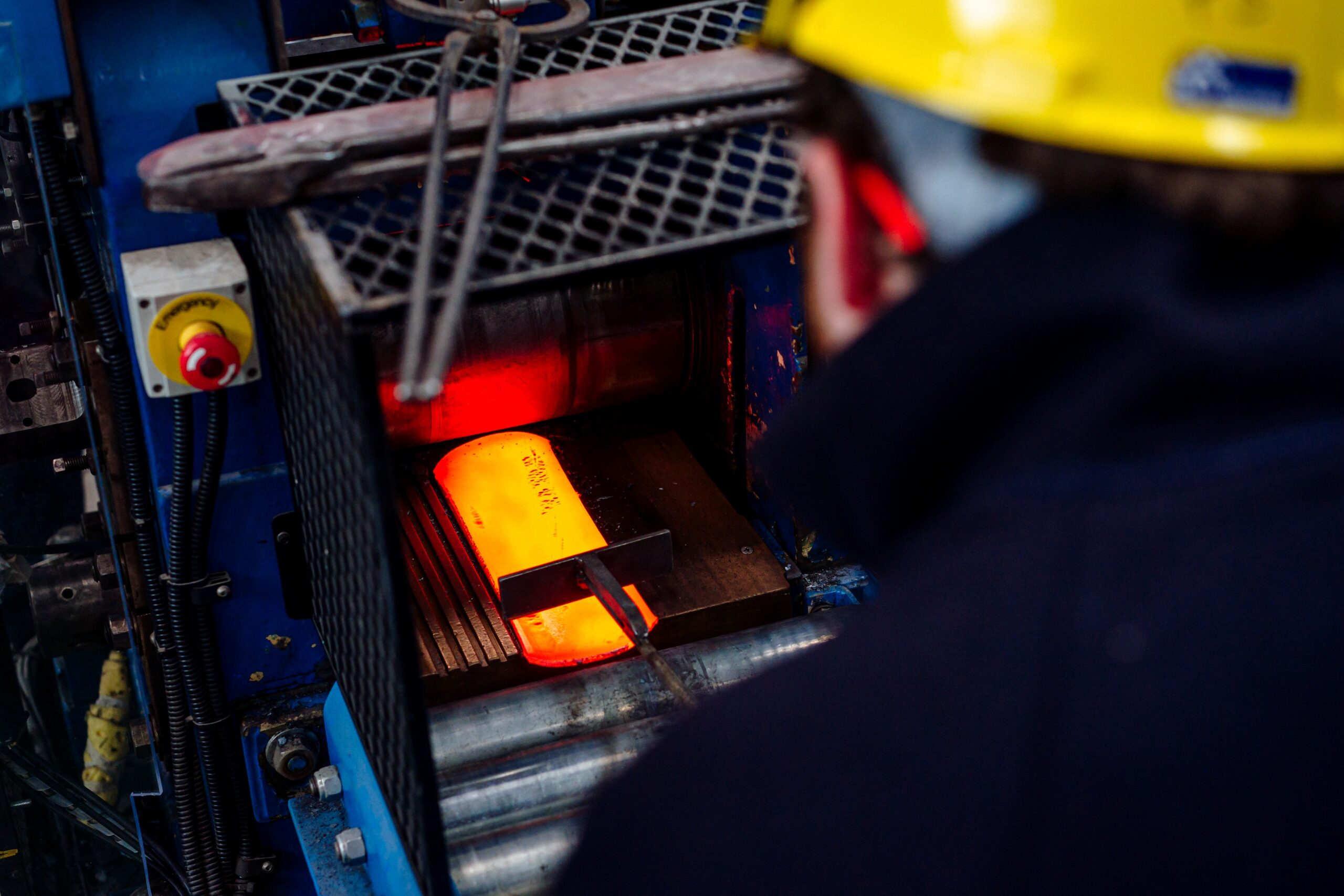

In our pilot lab we melt and process rolled sheets of metal samples. We then pass these samples to our characterisation team to provide an analysis. Analysis from the characterisation team reveals whether we hit our targets in the final composition of the alloy, in terms of the percentage of elements required.

All the materials we put in have different benefits to how the final alloy performs. Mechanical properties change depending on the percentage of elements. For example, steel is created for different industries such as automotive, packaging, transport, or defence. We adjust those elements for our customers to reach the ultimate percentage that gives their steel or metal the properties it needs for optimum performance in its products. We then revisit the process, to refine and roll more materials to get it right, before passing the samples back to our customers.

Refining our process for solutions

We refine our process based on feedback from other departments, allowing us to problem solve quicker and provide better solutions. We want to understand why something isn’t working and there’s a collaborative approach to find the answers.

We want to get the solutions industry need. Understanding why something isn’t working and making those changes to make it better is key to our approach to deliver real, practical solutions for industry.

Contributor James Evans

Updated January 2024